Industrial Maintenance & Welding

Career Focus

Prepared for immediate employment, advanced certifications, and further education.

Details

Students enrolled in the industrial maintenance technology associates degree or certificate program at NMU will learn how to install, maintain and repair different types of machinery. These are the required skills of high tech professionals who work in mines, paper mills, hospitals, and manufacturing. Industrial maintenance technicians are often referred to as millwrights.

What You Will Learn

Students will learn the correct process for installation, alignment, and maintenance procedures of various machinery components including setting and alignment of:

- Conveyors

- Gears/gearboxes

- Couplings

- Sheave belt systems

Additionally, students will become knowledgeable in:

- Equipment and tool safety

- Blueprint reading

- Precision measurement

- Steel identification

- Fabrication techniques

- Fastener identification

- Employability skills

Resources

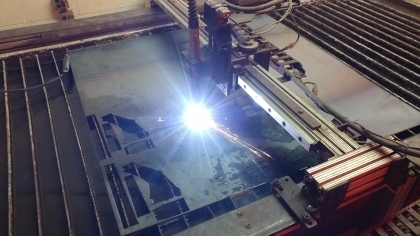

Photo Gallery

-

Click to see a larger version

Skip to end of gallery

Skip to start of gallery

Click to see a larger version

Skip to end of gallery

Skip to start of gallery

-

Click to see a larger version

Skip to end of gallery

Skip to start of gallery

Click to see a larger version

Skip to end of gallery

Skip to start of gallery

-

Click to see a larger version

Skip to end of gallery

Skip to start of gallery

Click to see a larger version

Skip to end of gallery

Skip to start of gallery

-

Click to see a larger version

Skip to end of gallery

Skip to start of gallery

Click to see a larger version

Skip to end of gallery

Skip to start of gallery

Career Ladder

Bachelor's Degree or Higher

- Architects, Except Landscape

- Architectural and Engineering Managers

- Career/Technical Education Teachers

- Commercial and Industrial Designers

- Engineers

- General and Operations Managers

- Industrial Production Managers

- Purchasing Managers

Associate's Degree, Long-Term Training & Apprenticeships

- Architectural and Civil Drafters

- Boilermakers

- Computer Numerically Controlled Machine Tool Programmers

- Drafters, All Other

- Mechanical Drafters

- Civil Engineering Technicians

- Industrial Engineering Technicians

- Jewelers and Precious Stone and Metal Workers

- Machinists

- Mechanical Engineering Technicians

- Millwrights

- Plumbers, Pipefitters, Steamfitters

- Power Plant Operators

- Sheet Metal Workers

- Structural Iron and Steel Workers

- Tool and Die Makers

- Water and Wastewater Treatment Plant and System Operators

- Wind Turbine Service Technicians

Certificate or Moderate-Term Training

- Chemical Equipment Operators

- Computer-Controlled Machine Tool Operators

- Furnace, Kiln, Oven, Drier, and Kettle Operators

- Inspectors, Testers, Sorters, Samplers, and Weighers

- Installation, Maintenance, and Repair Workers

- Machine Setters

- Maintenance Workers, Machinery

- Mechanical Door Repairers

- Medical Equipment Repairers

- Structural Metal Fabricators and Fitters

- Tool Grinders, Filers, and Sharpeners

- Welders, Cutters, Solderers, and Brazers

High School Diploma or Equivalent & Short-Term Training

- Cutting and Slicing Machine Setters, Operators

- Helpers--Installation, Maintenance, and Repair Workers

- Helpers--Pipelayers, Plumbers, Pipefitters, and Steamfitters

- Helpers--Production Workers

- Sawing Machine Setters, Operators

- Supervisors of Mechanics, Installers and Repairers

- Supervisors of Production and Operating Workers

- Woodworking Machine Setters, Operators

High School Credit

Students should inquire within their guidance office about high school curriculum requirements that may be satisfied through a college course, as this is determined individually by school district.

College Credit

Students earn direct college credits from NMU at no cost.

Industry Certification

Industry-recognized Certification

- OSHA 30-hour card for General Industry Safety*

- American Welding Society (AWS) certifications*

*Credentials are nationally recognized, portable and stackable, which means students have the option of attaining more advanced credentials in the future.

Success Story

Welding Students Tour Manufacturing!

MARESA CTE welding students toured BOSS Snowplow and Systems Control in Iron Mountain. Students learned they can find a good career in the UP!

More than 40 MARESA CTE welding students toured BOSS Snowplow and Systems Control manufacturing in Iron Mountain. Students learned they can find immediate employment and the beginning of a good career here in the UP.

More than 40 MARESA CTE welding students toured BOSS Snowplow and Systems Control manufacturing in Iron Mountain. Students learned they can find immediate employment and the beginning of a good career here in the UP.

BOSS moves 150,000 lbs of steel down their production line per day and uses 50 miles of MiG wire per day! BOSS designs and builds all kinds of snowplows, from the standard plow seen on pick-up trucks to smaller UTV and ATV plows, to the big box plows seen on front end loaders clearing large parking lots in the winter. They produce about 40 snowplows a month and they are shipped all over the world. Every BOSS plow you see was made in Iron Mountain, MI.

Systems Control designs and constructs Power Distribution houses. Systems Control produces about 25 sheds per month. The sheds range in size and cost, anywhere from $150,000 to $3 million per shed. The sheds are shipped all over world and range in weight from 16 - 30 tons each.

Both manufacturers are continually looking for quality employees for their skilled labor positions.

The tours were made possible through collaborative efforts between Marquette-Alger RESA and Michigan Works / Upward, and of course the welcoming hosts, Systems Control and BOSS Snowplow!

Want to Learn More?